Let loose Efficiency in Your Stockroom Operations With a Top Notch Stretch Covering Equipment

The introduction of a high-quality stretch covering maker can be a game-changer, promising efficiency, lowered labor prices, and lessened human error. With the ability to manage various lots sizes and wrap countless pallets per hour, these makers provide an engaging proposal for any kind of service looking to optimize its procedures.

Recognizing the Function of Stretch Covering Machines in Storehouse Operations

In the huge realm of stockroom operations, the value of stretch wrapping equipments can not be overstated. They offer a crucial duty in ensuring that items are safely and firmly bundled for storage or transportation. These devices use an extremely elastic plastic film around products, snugly wrapping them together in a manner that hands-on covering simply can not match.

Stretch covering makers can take care of large volumes of goods quickly, dramatically speeding up the packaging process. The consistent wrapping provided by these machines can lower the danger of meddling or burglary throughout transit.

Secret Functions of High-Quality Stretch Wrapping Machines

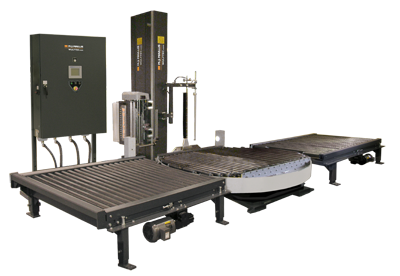

While there is a variety of stretch covering devices available out there, top quality versions share particular essential attributes that set them apart. These equipments are usually durable, developed to hold up against significant use without endangering on performance. They supply a high degree of automation, permitting convenient and efficient covering of items.

High-quality stretch wrapping equipments also feature flexible settings, offering adaptability to match various packaging demands. They can handle various dimensions and sorts of tons, making certain a secure wrap whenever. These equipments are also renowned for their speed, with the ability of covering numerous pallets per hour, therefore substantially enhancing productivity.

Another secret attribute is their integrity and low maintenance demand. High-grade machines are developed to last, reducing the frequency of break downs and the linked downtime. They operate with precision, making sure regular cover stress, consequently minimizing waste and improving the presentation of wrapped products.

The Influence of Stretch Wrapping Equipments on Storehouse Performance

The performance of a stockroom can be dramatically improved with making use of high-grade stretch covering machines - stretch wrapping machine. These equipments enhance the product packaging procedure, minimizing the manual work entailed and as a result, the chance for human mistake. This makes certain a much more dependable and regular wrapping procedure, causing improved security of goods throughout transport

In addition, stretch wrapping equipments can manage a greater volume of items in a much shorter quantity of time compared to manual covering. This heightened performance can lead to far better usage of warehouse area as items can be packaged and moved quicker. The makers additionally provide the adaptability to accommodate various shapes and sizes of products, better enhancing see this page functional performance.

Computing the Roi for a Stretch Covering Device

Considering the substantial benefits of stretch wrapping devices, it's essential to recognize the economic ramifications of purchasing such tools. The roi (ROI) calculation is a simple yet reliable tool to assess the productivity of this financial investment. The ROI is calculated by contrasting the cost of the equipment with the cost savings generated over a details period.

Organizations need to additionally think about elements such as tactical alignment, functional performance, and scalability. In final thought, determining the ROI provides a clear economic viewpoint to direct the investment choice in stretch covering devices.

Real-world Case Studies: Success Stories of Applying Stretch Wrapping Machines

Drawing from the economic ramifications discussed in the previous area, it is similarly enlightening to check out useful applications and success tales of business that have actually executed stretch covering makers in their operations. One such instance is an international electronic devices firm which reported a 30% reduction in damaged items during transit after introducing stretch covering devices in their packaging procedure.

One more success tale involves a leading food and drink company. After implementing a stretch wrapping equipment, they experienced a significant enhancement in their product packaging speed, which subsequently enhanced daily results and overall efficiency.

Finally, a popular furnishings manufacturer was able to lower their packaging material prices by a shocking 40% after switching over to extend wrapping makers; they concurrently reduced their carbon footprint, making their procedures extra sustainable. These real-world situation researches show the outstanding returns and effectiveness gains that extend wrapping devices can give stockroom operations.

Conclusion

In final thought, purchasing a premium stretch covering maker can substantially enhance storehouse procedures. With its capacity to lower manual labor, minimize errors, and improve space usage, it considerably boosts visit this site productivity and success. The ROI, combined with success stories from real-world applications, even more highlights Get the facts the important function of stretch wrapping devices in accomplishing functional effectiveness and company success.

The introduction of a premium stretch wrapping device can be a game-changer, promising efficiency, reduced labor prices, and reduced human error.In the large realm of stockroom procedures, the relevance of stretch wrapping devices can not be overstated.The performance of a warehouse can be significantly boosted with the usage of top notch stretch wrapping machines.Moreover, stretch covering devices can deal with a greater quantity of products in a shorter quantity of time compared to manual covering.In final thought, investing in a high-grade stretch covering machine can dramatically improve storage facility procedures.

Comments on “How a stretch wrapping machine cuts down on packaging waste”